FSEPC

Certified Inspection, NDT, & EPC Oversight

FSEPC - Certified Inspection & EPC Oversight

-

Construction Manager / EPC Oversight

Oversee projects from planning to completion

-

Chief Inspector

Coordinate construction & inspection activities. Verifying & ensure regulatory compliance

-

Welding Inspector - CWI/CPWI

Confirm weld quality and adherence to standards

-

Coating Inspector - NACE/AMPP

Ensure proper coating applications for corrosion protection

-

Civil Inspector

Verify site materials and engineering specifications

-

Utility Inspectors

Supervise utility installations, repairs, and maintenance

-

Cathodic Protection Inspector

Monitor corrosion prevention systems

-

Electrical & Instrumentation Inspector

Safe, code-compliant installations and rigorous quality oversight across electrical and control systems

-

API Inspector

Assess pipelines, tanks, and pressure vessels

-

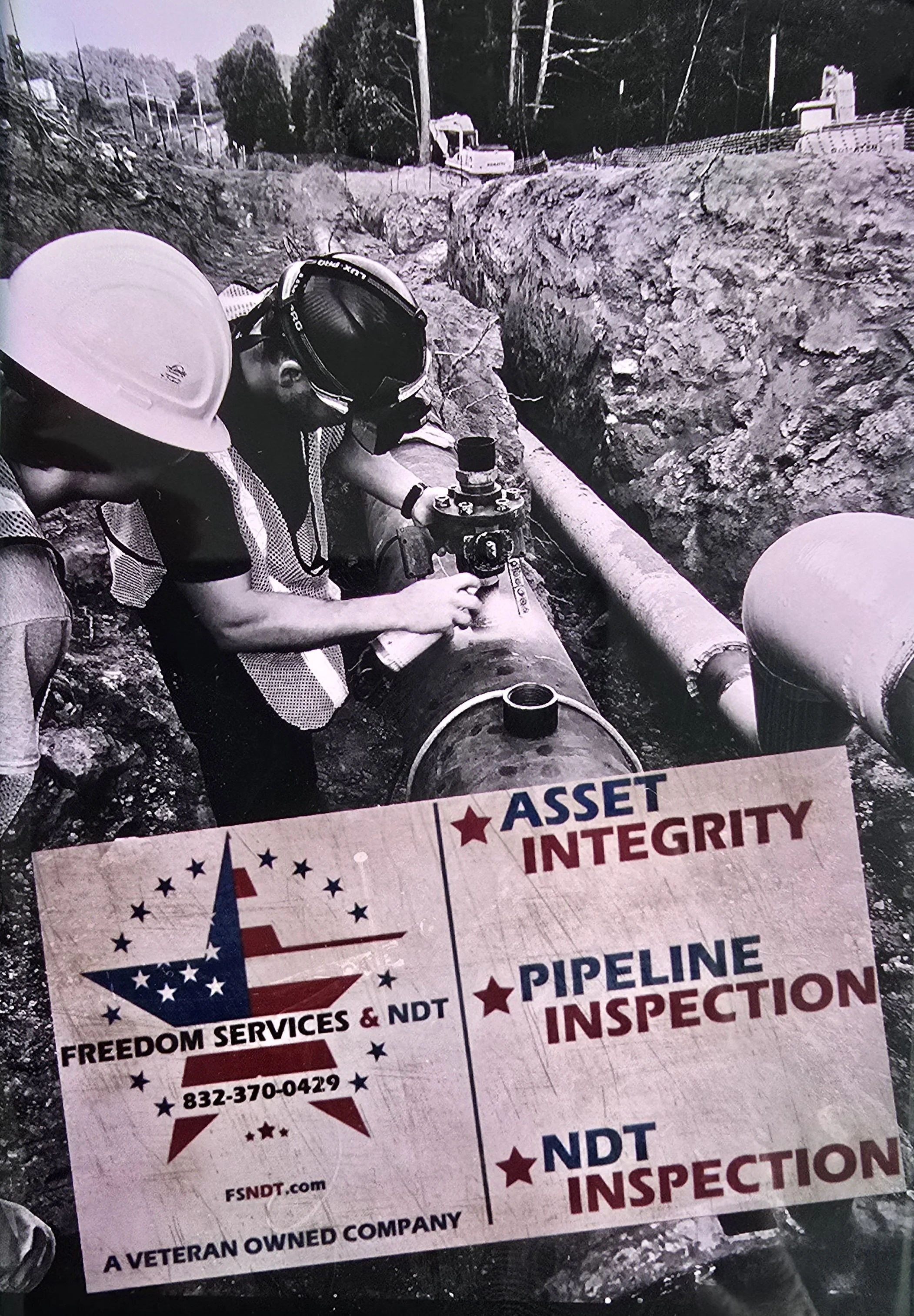

Integrity Inspector

Evaluate pipelines, facilities, and equipment

-

Tank Inspector

Assess storage tanks for structural integrity

-

Environmental Inspector

Maintain eco-friendly, compliant operations

-

Quality Control Specialists

Enforce QA/QC processes and compliance

-

Material Expeditors

Track and manage materials efficiently

-

Project Managers / Office Managers

Plan, organize, and lead projects

-

Production Facility Consultants

Optimize facility design and operations

-

Safety Inspector

Implement and monitor safety protocols

-

Gate Guards

Secure site access and maintain logs

FSEPC NDT DIVISION

-

Certify welders (API/ASME) on you job site!

-

Validate weld integrity through expert film reviews

-

Convert traditional radiographic film into high-resolution digital format, ensuring long-term preservation, improved image clarity, and easier storage, retrieval, and sharing for audits, reporting, and quality documentation.

-

Detect internal flaws and measure wall thickness

-

Verify weld quality and internal material soundness using X-ray/Gamma methods

-

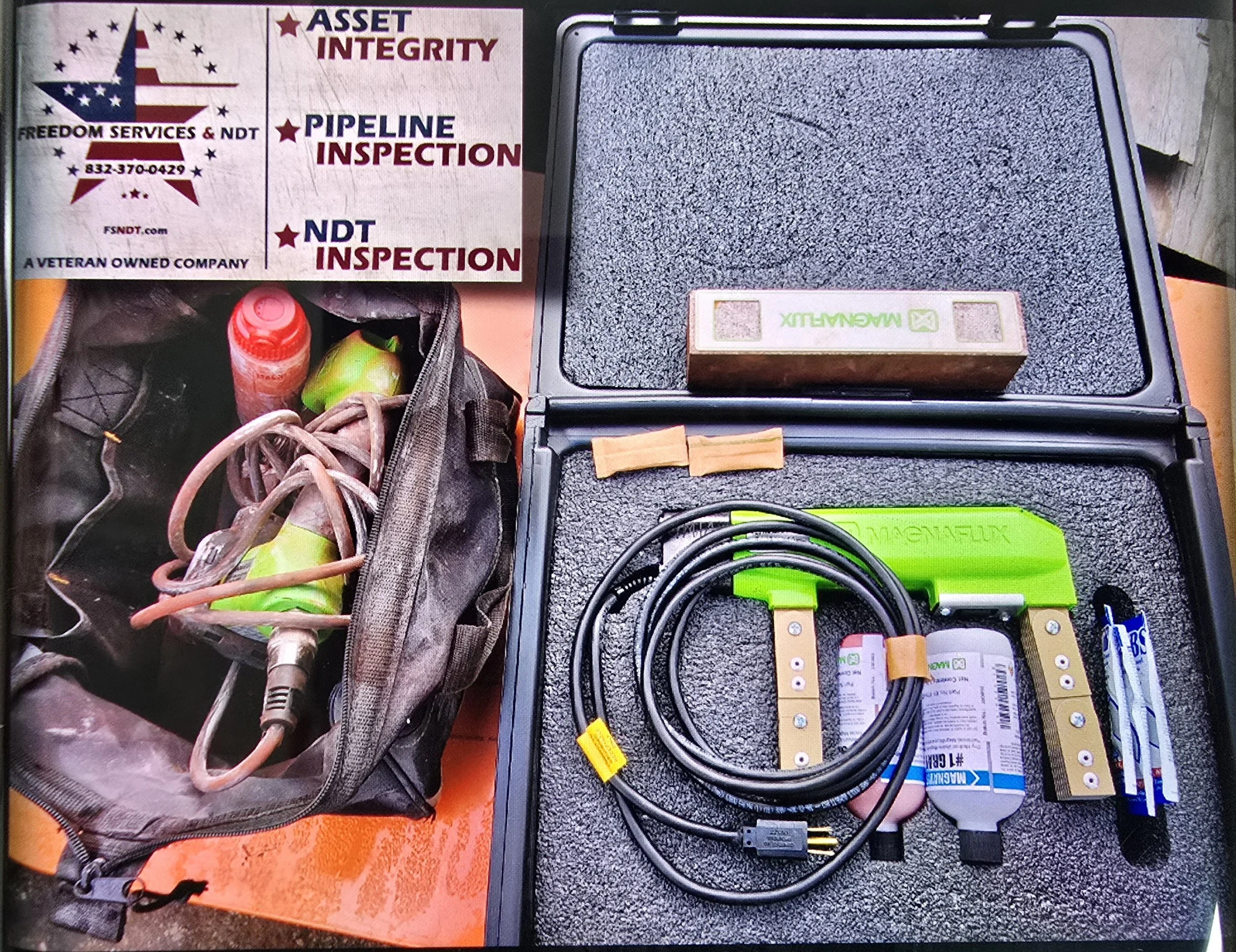

Identify surface and near-surface discontinuities in ferromagnetic materials

-

Reveal surface-breaking defects in non-porous materials

-

Perform direct and enhanced visual examinations to confirm workmanship and compliance

-

Measure material hardness to verify heat treatment and mechanical properties

-

Confirm material chemistry and alloy composition for specification compliance